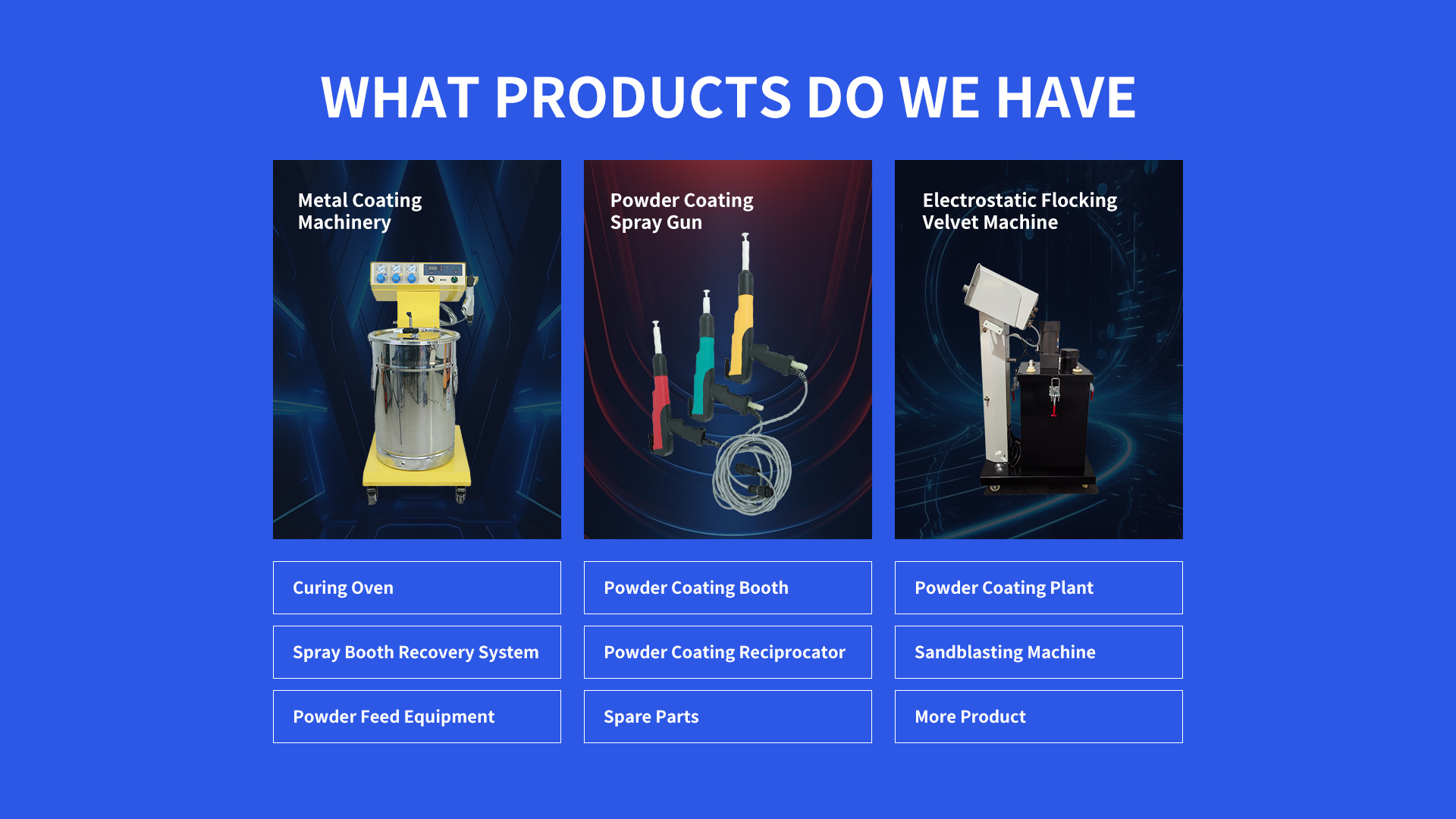

Powder Coating Gun is a fundamental tool in the realm of powder coating, enabling the application of a wide variety of powder finishes with precision.

The working principle of a

Powder Coating Gun typically involves electrostatic charging. There are two main charging methods: corona charging and tribo charging. In corona charging, a high - voltage electrode creates a corona discharge around the nozzle of the gun. This ionizes the air, and as the powder passes through this ionized field, it picks up a negative charge. The object to be coated is grounded, creating an electrostatic attraction that pulls the charged powder particles onto the surface. Tribo charging, on the other hand, charges the powder by friction as it passes through a special tube in the gun.

A

Powder Coating Gun consists of several key components. The powder hopper is where the powder is stored. It has a mechanism to regulate the flow of powder into the gun. The nozzle is crucial as it determines the spray pattern. Different nozzles can create a wide - fan, narrow - cone, or circular spray pattern. The gun also has an air supply system that helps in atomizing the powder and propelling it towards the object.

The performance characteristics of a

Powder Coating Gun are remarkable. It offers high transfer efficiency, meaning that a significant portion of the powder sprayed actually adheres to the object. This not only saves powder but also results in a more efficient coating process. The gun can achieve a very smooth and uniform finish, which is essential for applications where aesthetics matter. For example, in the automotive industry, a smooth finish on wheels or body parts is highly desirable.

Powder Coating Guns find applications in numerous industries. In the furniture industry, they are used to coat metal furniture frames, providing a durable and attractive finish. For instance, a powder - coated metal chair frame can withstand daily wear and tear while looking stylish. In the construction industry, the gun is used to coat metal structures like handrails and gates. This protects them from corrosion and gives them an aesthetically pleasing appearance.

When operating a

Powder Coating Gun, there are some important points to note. First, proper surface preparation of the object is crucial. The surface should be clean, free from grease, dirt, and rust. Sanding can also improve powder adhesion. Second, the operator needs to adjust the powder flow rate according to the size and shape of the object. For small, detailed objects, a lower powder flow rate is required, while larger objects can handle a higher rate. The air pressure also needs to be adjusted. Higher air pressure can create a finer spray but may also cause over - spraying.

Maintenance of the

Powder Coating Gun is essential for its long - term performance. Regularly clean the powder hopper to prevent powder caking. The nozzle should be cleaned after each use to avoid clogging. Check the air hoses for any leaks. Also, periodically inspect the charging system to ensure it is functioning correctly.

Common problems with

Powder Coating Guns include uneven coating. This can be due to an improper spray pattern, incorrect powder flow rate, or a dirty nozzle. Another issue is poor powder adhesion, which may be caused by improper surface preparation or a malfunctioning charging system. To solve these problems, ensure the gun is properly adjusted, the surface is well - prepared, and the charging system is in good working condition.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com